- ul. Antoniego Słomińskiego 1, 50-304 Wrocław

- Godziny otwarcia : Mon-Fri 08:00 - 16:00

Technologia HPP to metoda utrwalania

Twoich produktów!

Technologia HPP (High Pressure Processing) inaczej paskalizacja to metoda utrwalania żywności z wykorzystaniem wysokiego ciśnienia, bez konserwantów, w niskiej temperaturze. To nowoczesna metoda przedłużania trwałości produktów – zarówno spożywczych, jak i kosmetycznych. Polega ona na krótkotrwałym poddaniu produktu działaniu wysokiego ciśnienia, które zastępuje wysoką temperaturę lub substancje konserwujące.

Standard IFS Food jest skierowany do producentów żywności i ma na celu zapewnienie bezpieczeństwa w procesie produkcji żywności, pakowania, przechowywania i dystrybucji.

IFS Food wdrażany jest przez producentów marek własnych oraz firmy eksportujące żywność na rynki zagraniczne.

Standard IFS Food ma na celu dbać o bezpieczeństwo produktów od produkcji do momentu pakowania. Wymagania normy obejmują następujące obszary:

– odpowiedzialność kierownictwa;

– system zarządzania jakością (w tym HACCP);

– zarządzanie zasobami;

– planowanie i procesy produkcyjne;

– pomiary, analizy i ciągłe doskonalenie.

– obszar obrony żywności

Technologia HPP inaktywuje patogeny, odpowiedzialne za psucie się i choroby przenoszone przez żywność oraz znacznie wydłuża okres trwałości produktu. Stosowanie technologii HPP do utrwalania żywności i napojów – zamiast pasteryzacji w wysokiej temperaturze lub chemicznych środków konserwujących – dostarcza produkty, które są bezpieczne, mają znacznie dłuższy okres przydatności do spożycia oraz smakują i wyglądają jak świeże produkty, które klienci świadomi jakości chcą kupować.

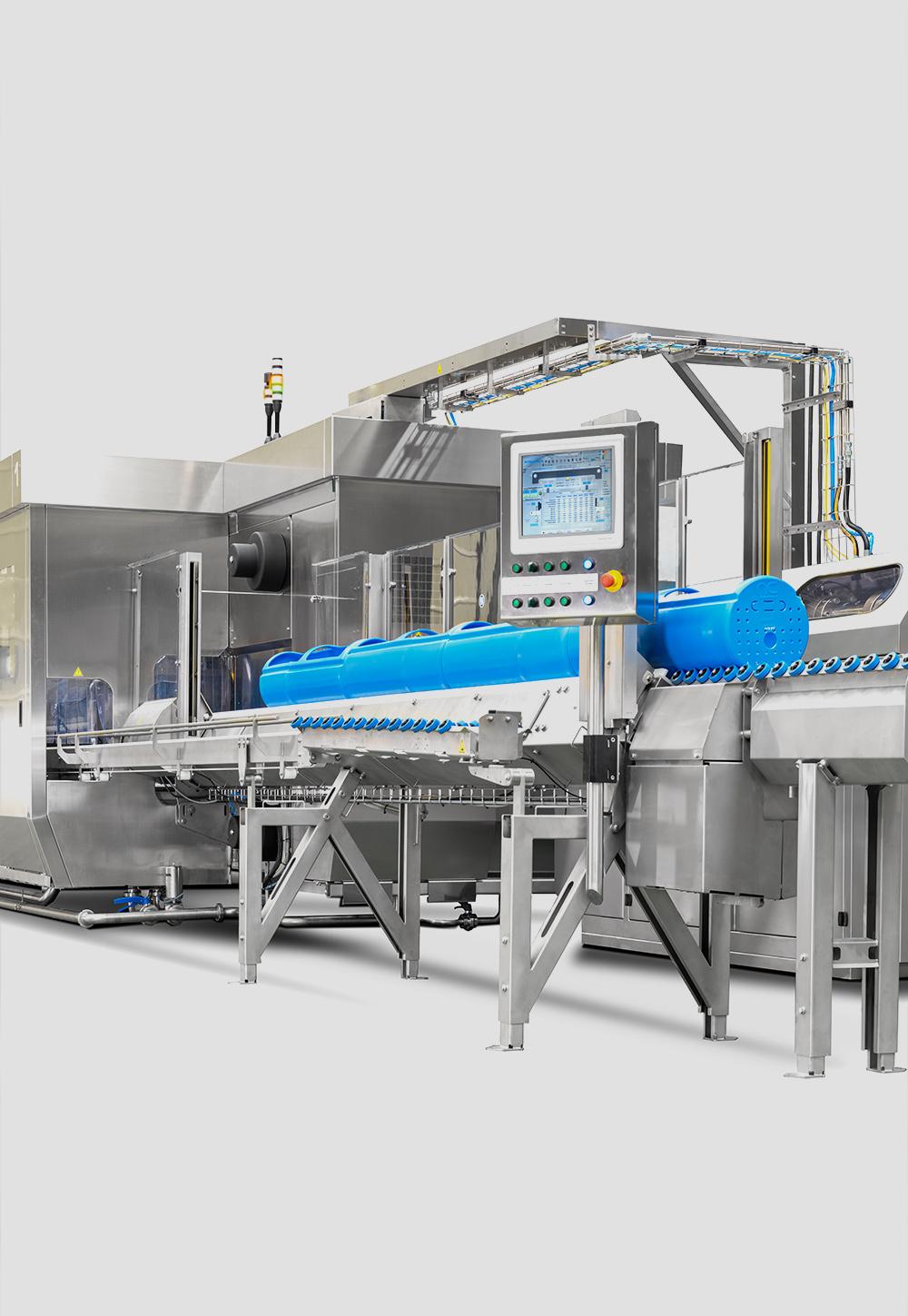

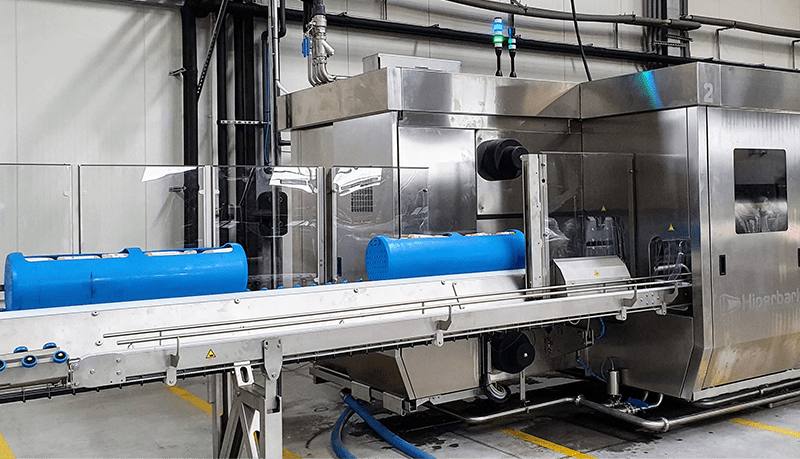

Paskalizacja produktów odbywa się po napełnieniu opakowań końcowych. Zgromadzone produkty są następnie umieszczane w jednostce do paskalizacji Hiperbaric, gdzie zostają zabezpieczone i poddane wysokiemu ciśnieniu przenoszonemu przez wodę. Kilka minut przebywania pod wpływem ciśnienia nawet 6000 barów wystarcza, by inaktywować bakterie (w tym także E.coli oraz salmonellę!), pleśń, grzyby i inne niebezpieczne patogeny, jednocześnie nie ingerując w strukturę samego produktu.

Podczas paskalizacji temperatura samego produktu utrzymuje się na odpowiednim dla niego poziomie (w zakresie pomiędzy 6 a 40℃). Po wyjęciu z jednostki, produkty są gotowe do transportu do miejsca ich magazynowania.

Technologia HPP zwalcza wirusy przenoszone przez żywność, związane z chorobami przewodu pokarmowego, takie jak zapalenie wątroby czy norowirusy. Badania nad technologią wykazały, że HPP skutecznie inaktywuje różne wirusy takie jak ptasia grypa, wirusy opryszczki pospolitej typu 1, ludzki cytomegalowirus, wirus pęcherzykowego zapalenia jamy ustnej i ptasi metapneumowirus.

Produkty do paskalizacji mogą mieć różne rodzaje opakowań plastikowych – od butelek, poprzez tacki, do opakowań próżniowych. Muszą jednak spełniać dwa podstawowe warunki:

Elastyczność i wodoodporność to jedyne wymagania. Nie ma praktycznie ograniczeń co do wielkości i ciężaru. Cała reszta zależy od produktu, wymagań rynku oraz… wyobraźni producenta!

Jak technologia HPP może poprawić jakość, trwałość i wartość marki twoich produktów?

Choć z opisu paskalizacja może wydawać się prosta, sam proces wymaga precyzji i nie ma tu miejsca na wątpliwej jakości sprzęt. Dlatego też – po wnikliwej analizie rynku – zdecydowaliśmy się w tej kwestii na ścisłą współpracę z producentem Hiperbaric, który jest niekwestionowanym światowym liderem w produkcji maszyn wykorzystujących technologię ciśnieniowego utrwalania.

Specjalizacja Hiperbaric w tej dziedzinie, rozpoznawalność, a przede wszystkim duże grono zadowolonych klientów sprawia, że mamy pewność jakości, jaką sami możemy zaoferować naszym klientom.

HPP TradeBridge Sp. z o.o.

Centrum Usługowe

Copyright © 2022. All rights reserved.

MarketingPoint360.com

WhatsApp us

Technologia HPP skutecznie zabija szkodliwe bakterie i wydłuża okres przydatności do spożycia szerokiej gamy produktów białkowych, zarówno surowych, jak i gotowanych. Stosowanie HPP do gotowanego mięsa często eliminuje potrzebę stosowania sztucznych konserwantów, aby przedłużyć okres przydatności do spożycia i zabić organizmy powodujące psucie się mięsa. Wysokie ciśnienie jest również doskonałym rozwiązaniem dla surowego białka, takiego jak mielony indyk i pierś z kurczaka, niszczących bakterie i patogeny, które powodują choroby i znacznie wydłużając okres przydatności do spożycia. Producenci cenią sobie możliwość oferowania świeżych, nigdy nie podgrzewanych, gotowych do przygotowania posiłków produktów premium coraz bardziej wymagającym i świadomym jakości klientom.

HPP to skuteczna metoda pasteryzacji bez ciepła dla szerokiej gamy mięs.

Jakie produkty można poddać procesowi paskalizacji?

Plastikowe pojemniki z uszczelnieniami indukcyjnymi/termicznymi, MAP (opakowanie w zmodyfikowanej atmosferze), plastikowymi próżniowymi i opakowaniami typu kleń – wszystko to dobrze sprawdza się w przypadku produktów białkowych i procesu HPP. Skontaktuj się z nami, aby uzyskać więcej informacji na temat mięs HPP i wymagań dotyczących pakowania.